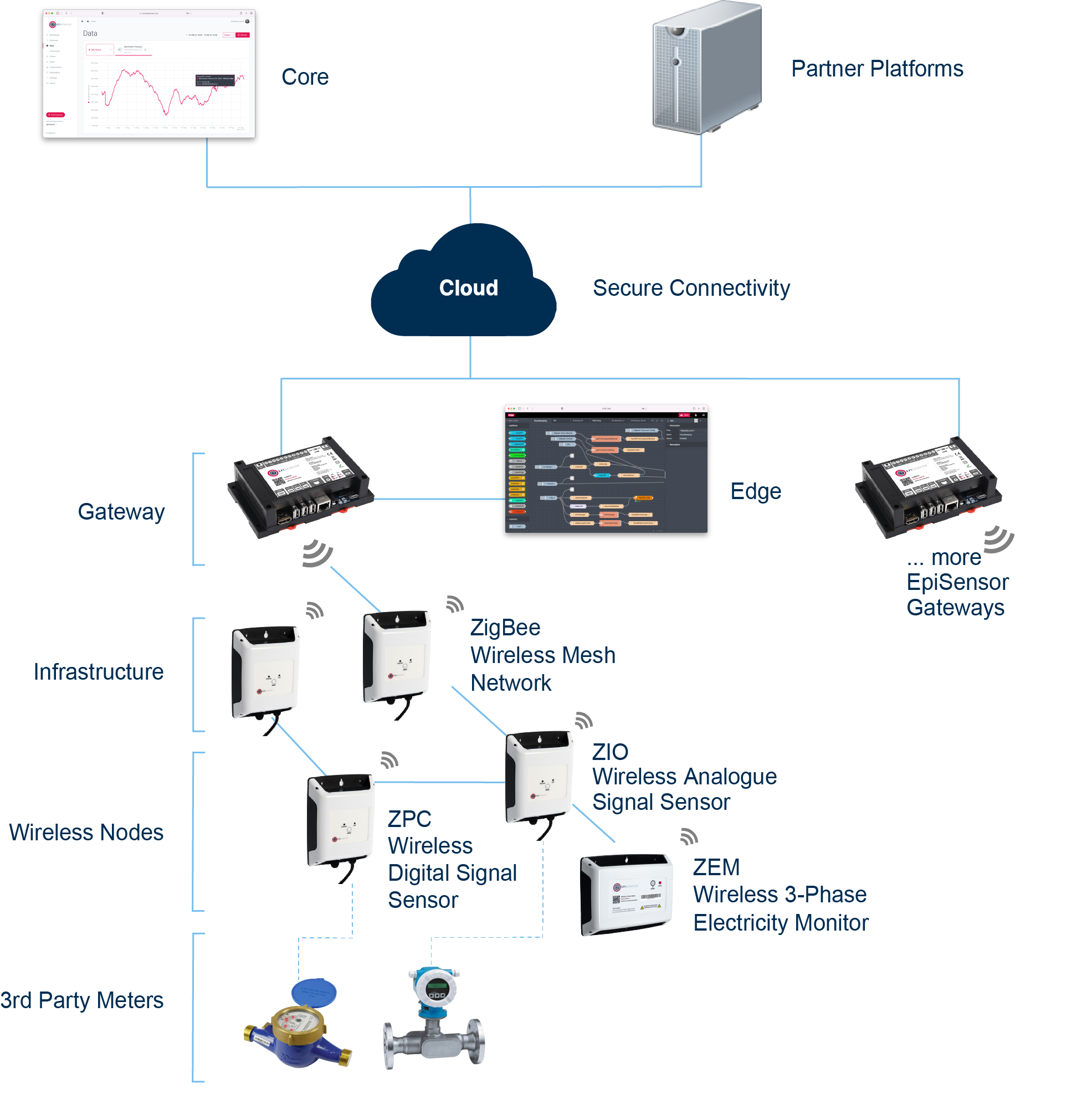

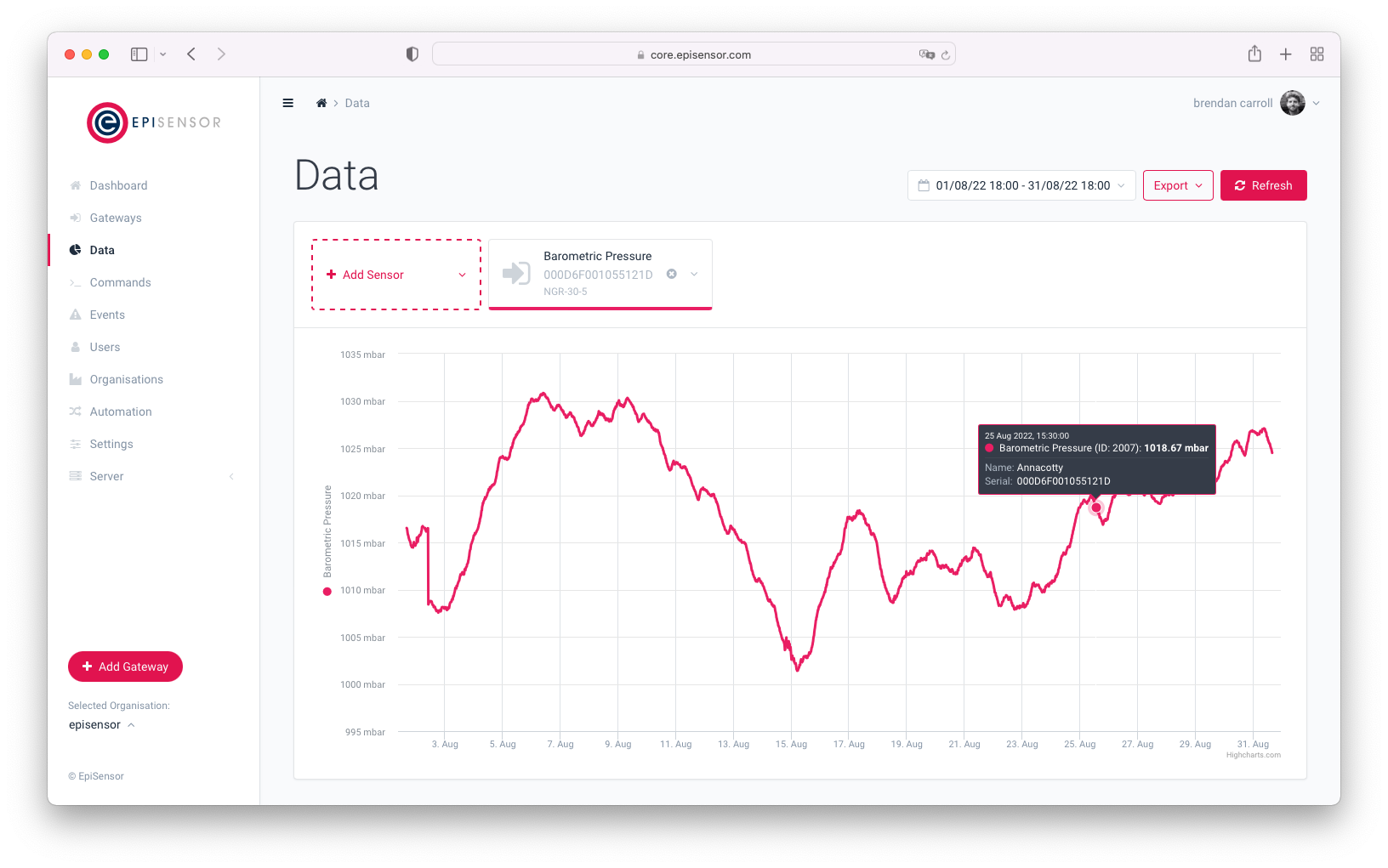

We design, make and deliver reliable, secure and highly accurate wireless energy monitoring systems for commercial and industrial use.

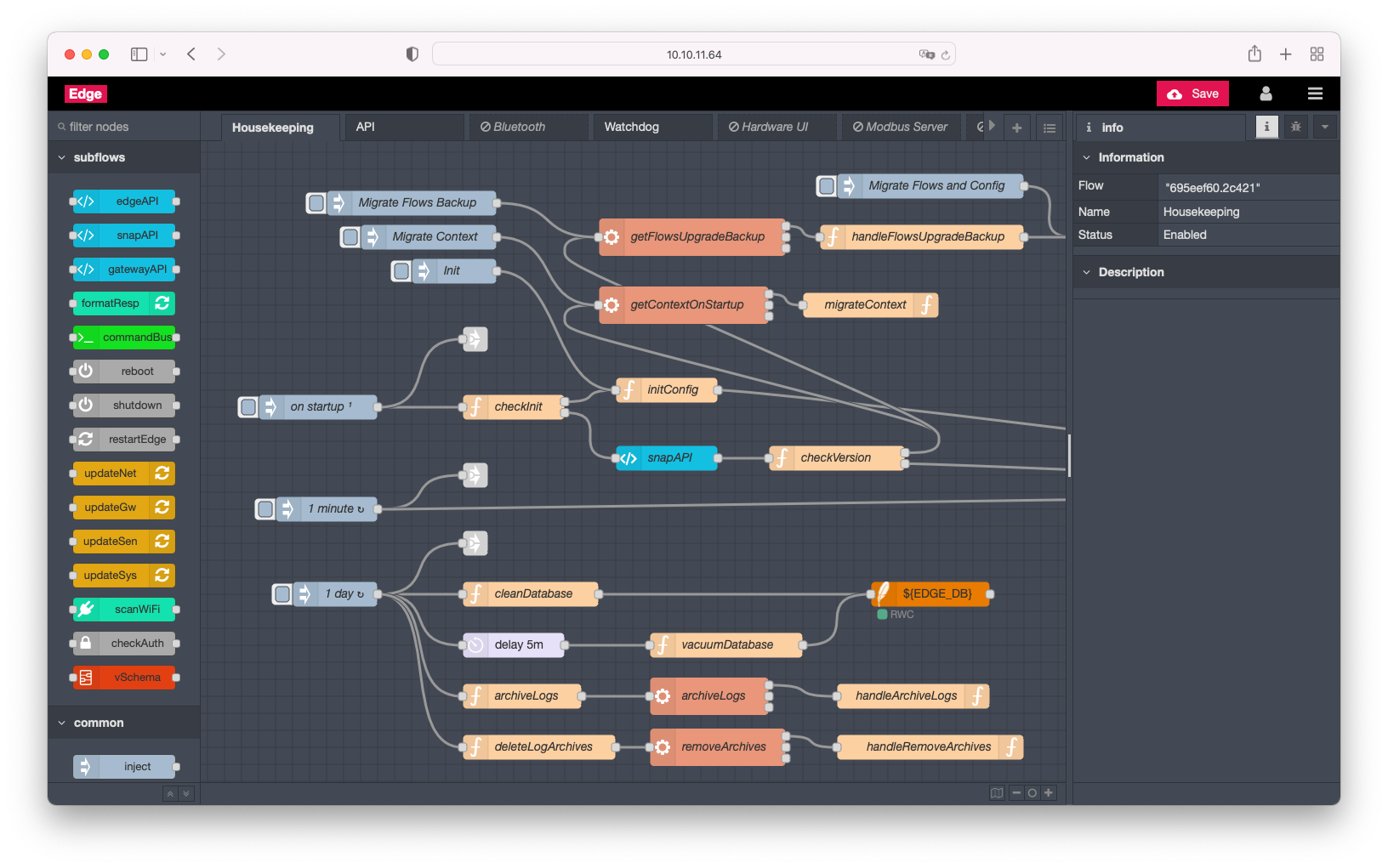

Our partners win projects in harsh environments where performance and security are crucial – because no one else can match our capabilities or ease-of-use.