Company

Capula

Headquarters

Mayfair, London

Industry

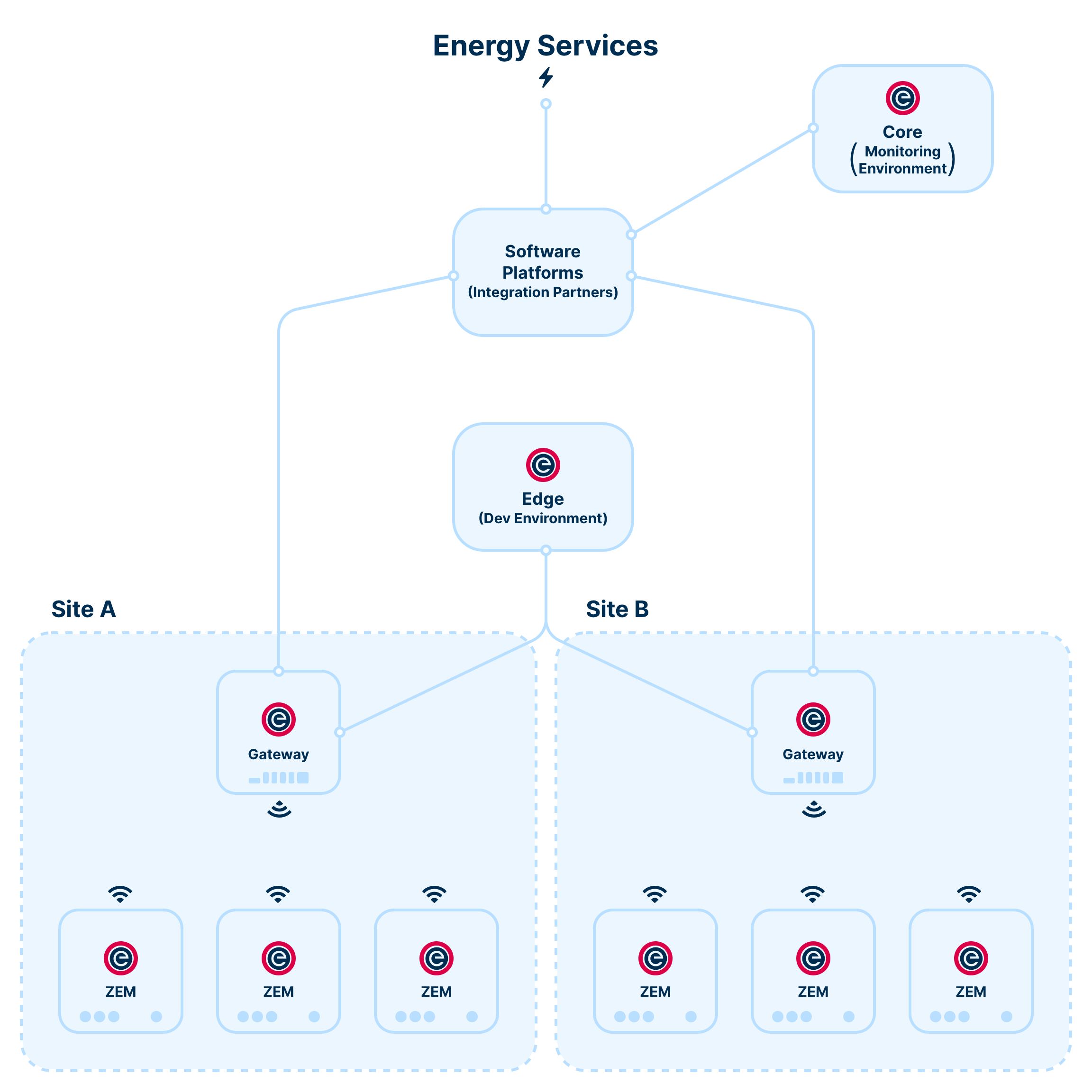

Energy Services

Key Products Used

Key Points of Interest

- Rapid-install reduced overall project costs

- Highly-secure, proven technology

- Wireless, mesh and Zigbee technologies

- 5A/250V switching capability

- Measurement range 0.1A to 3kA

- Chosen for scalability