Company

Headquarters

Cork, Ireland

Industry

Life Sciences, Pharmaceuticals

Key Products Used

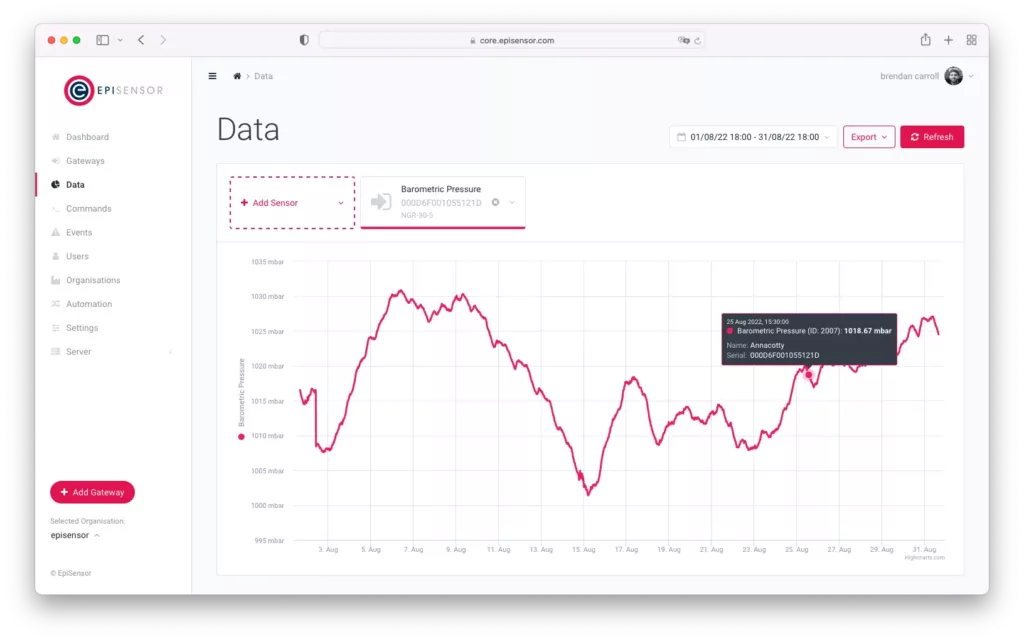

- Industrial IoT Gateway

- Wireless 3-Phase Electricity Monitor (ZEM)

- ZPC Wireless Digital Signal Sensor

Key Points of Interest

Gas, water, and electricity are monitored through a single system.

EpiSensor technology is helping Merck Ireland meet ambitious sustainability targets set by the group.

The EpiSensor system is growing alongside Merck Ireland as its footprint expands.