Introduction to Pulse Outputs

A pulse output is a digital signal representing electricity consumption or other utilities, such as water, gas, or heat. These outputs are produced by metering equipment, where each pulse corresponds to a specific amount of consumption. For instance, in energy meters, a pulse might indicate the consumption of 1 kilowatt-hour (kWh). Counting and tracking these pulses over time allows higher-level systems to monitor and analyse utility usage effectively.

This article explores the technical aspects of interfacing with pulse outputs in energy monitoring programmes, focusing on key considerations such as pulse multipliers, pulse rates, voltage specifications, and types of pulse outputs.

Pulse Multiplier: Understanding Conversion

The pulse multiplier is a critical parameter that converts the utility consumption into pulses. It defines how much utility usage each pulse represents. For example, a multiplier of 10 pulses per kWh means that 1 pulse is generated for every 0.1 kWh consumed. Understanding and correctly configuring the pulse multiplier is essential for accurate data collection and analysis in energy monitoring.

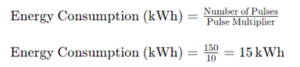

Example Calculation:

If a pulse meter has a multiplier of 10 pulses/kWh, and a system records 150 pulses in an hour, the energy consumption can be calculated as:

This simple calculation illustrates the importance of knowing the pulse multiplier to derive meaningful data from pulse counts.

Maximum Pulse Rate: Ensuring System Compatibility

The maximum pulse rate is the highest frequency at which pulses can be generated and reliably detected by energy monitoring equipment. This rate is typically specified in pulses per second or Hertz (Hz). Understanding the maximum pulse rate is crucial because exceeding this rate can lead to data loss or inaccuracies, especially in high-consumption scenarios or with battery-powered monitoring devices.

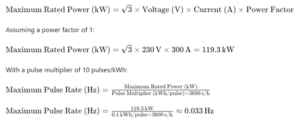

Calculating Maximum Pulse Rate:

To calculate the maximum pulse rate, consider the maximum expected power consumption and the pulse multiplier. For instance, in a 3-phase system with a maximum rated current of 300A per phase and a nominal voltage of 230V, the maximum rated power would be:

This calculation ensures the monitoring equipment can handle the expected pulse rate without data loss.

Pulse Output Voltage: Matching Specifications

Pulse output voltage can vary based on the metering equipment used. Many pulse outputs are “volt-free” or “dry contacts,” where the pulse is produced by closing a circuit without voltage. Other systems produce pulses by a voltage going high, where the pulse output involves a change in voltage level. It’s crucial to ensure that the voltage of the pulse output matches the specifications of the energy monitoring equipment to avoid damage or inaccuracies.

Voltage Considerations:

- Volt-Free Outputs: Typically involve mechanical or solid-state relays that close a circuit, allowing current to flow without applying voltage. These are common in older or simpler metering devices.

- Voltage-Driven Outputs: These involve a specific voltage level change, such as a transition from 0V to a defined higher voltage (e.g., 5V, 12V, 24V). The monitoring equipment must support the expected voltage levels to detect and record pulses accurately.

Types of Pulse Outputs: Selecting the Right Interface

Metering equipment can produce pulse outputs using various technologies. Understanding these types is essential for selecting the appropriate interface for your monitoring system.

Common Pulse Output Types:

- Hall Effect Sensors: Generate pulses based on magnetic fields and can produce PNP (‘sourcing’) or NPN (‘sinking’) outputs. These sensors are often used in applications requiring isolation or robust signal transmission.

- Optical Sensors: Detect changes in light and produce digital pulses. They are used in environments where physical contact is undesirable or where high precision is required.

- Reed Switches: Use a magnetic field to close or open a circuit, generating pulses. These are commonly found in simple, low-cost metering devices.

- Mechanical Relays: Provide dry contact pulses by physically turning on or off a switch. Suitable for applications where electrical isolation is essential.

Selecting the right type of pulse output depends on the specific requirements of the monitoring application, including environmental conditions, signal accuracy, and isolation needs.

Struggling to find metering equipment to meet your needs?

Talk to one of our experts who will guide you through the selection process

Minimum Pulse Duration: Ensuring Accurate Detection

The minimum pulse duration, or width, is the shortest time interval for which a pulse must be present to be reliably detected by the monitoring equipment. This parameter is critical because pulses that are too short may not be registered, leading to under-reporting of consumption.

Typical Pulse Duration Considerations:

- Short Pulse Durations: Common in high-frequency applications or systems with fast consumption rates. Monitoring equipment must have a high sampling rate to detect short pulses accurately.

- Longer Pulse Durations: Found in systems with slower consumption rates or older metering technology. These pulses are easier to detect but may require synchronization with the monitoring equipment’s sampling interval.

Ensuring the pulse duration is compatible with the monitoring equipment’s capabilities is crucial for accurate data collection.

Monitoring in Hazardous Environments

In hazardous or EX environments, safety regulations may require optical isolation between the equipment producing and monitoring the pulse. This isolation prevents electrical hazards and ensures safe operation.

Optical Isolation:

- Optocouplers: Use light to transmit signals across an isolation barrier. They provide electrical isolation and are ideal for interfacing between different voltage levels or in environments where electrical noise is a concern.

- Transformers: Provide galvanic isolation by transferring the pulse signal through electromagnetic induction. Suitable for high-voltage or industrial applications where robust isolation is needed.

Compliance with safety standards and regulations is mandatory when designing systems for hazardous environments.

KY and KYZ Pulse Outputs: Differentiating Use Cases

KY and KYZ pulses offer different functionalities based on the application’s needs. Understanding their differences helps in selecting the appropriate pulse type for specific monitoring requirements.

KY Pulse Outputs:

- Basic Consumption Data: Provide a single pulse stream indicating utility consumption. Suitable for straightforward energy monitoring applications where only total consumption data is required.

KYZ Pulse Outputs:

- Direction and Type of Power Flow: Provide multiple pulse streams, allowing the distinction between different types of consumption (e.g., active and reactive power) or power flow directions. Useful in complex energy management systems requiring detailed analysis of power usage patterns.

Choosing between KY and KYZ pulses depends on whether the application needs detailed power flow information or simple consumption tracking.

Alternatives to Pulse Outputs: Enhancing Data Granularity

While pulse outputs are effective for basic consumption monitoring, more granular data may be required for advanced energy management applications. Alternatives like Modbus or serial communications offer detailed data and higher resolution.

Modbus and Serial Communications:

- High-Resolution Data: Provide continuous, real-time data on various parameters such as voltage, current, power, and energy consumption. Suitable for applications needing detailed monitoring and control.

- Complex Integration: Requires compatible hardware and software for data acquisition and analysis. More complex than pulse output systems but offers greater flexibility and accuracy.

Comparison with Pulse Outputs:

- Pulse Outputs: Simple, cost-effective, and suitable for basic consumption monitoring.

- Modbus/Serial: More detailed, complex, and suitable for advanced energy management and analysis.

Leveraging EpiSensor Products for Pulse Monitoring

EpiSensor’s Wireless Digital Signal Sensor (ZPC/ZDI) excels in monitoring pulse signals from a wide variety of third-party metering equipment. Our specialised infrastructure supports various pulse types and is configurable to accommodate different pulse multipliers, rates, and voltages, making it adaptable to various commercial and industrial settings. EpiSensor’s solutions provide highly accurate data analytics and are easily integrated with various software platforms, BIM’s, and SCADA systems, enhancing your energy monitoring and management capabilities. Furthermore, EpiSensor infrastructure is easy to install and 10x easier to use than traditional automation and control systems—two of the many reasons we are IoT partners to global leaders in facilities management and systems integration.

Key Features of EpiSensor Products:

- Compatibility: Supports integration with diverse pulse output types and metering equipment.

- Flexible Configuration: Allows adjustment of pulse multiplier settings, ensuring accurate data collection.

- Advanced Analytics: Provides tools for detailed data analysis and reporting, integrating seamlessly with a wide variety of systems for comprehensive energy management.

Have further technical questions you need answered? Tap into the EpiSensor Knowledge Base today!

Discover whether EpiSensor products are the right fit for your project

Find out more about product features and suitability